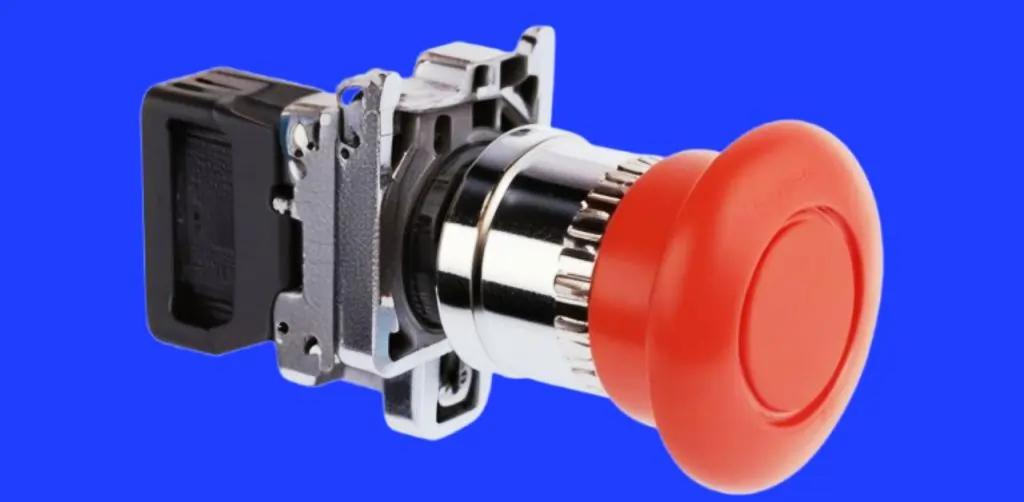

Emergency Stop Push Button

In the marine industry, where powerful machinery and electrical systems are at the heart of every vessel’s operation—from propulsion systems to essential navigation and safety equipment—safety protocols are critical. Amid these advanced, high-powered systems, the risk of physical injuries remains a serious concern, especially in confined and often turbulent environments. Emergency stop push buttons play a crucial role in marine safety by providing a quick and effective way to halt machinery instantly, preventing potential accidents and protecting crew members from harm. In this guide, we’ll explore the various types of emergency stop push buttons specifically for marine applications, their functionality, and how they enhance safety on board.

What is an Emergency Stop Push Button?

An emergency stop push button is a crucial safety device commonly used in industrial and marine sectors, particularly in environments with heavy-duty machinery and high-load equipment. This fail-safe control switch is designed to immediately halt machinery operation in emergency situations, protecting operators, machinery, and surrounding areas from potential harm. Often referred to as a “kill switch” or “Estop switch,” the emergency stop push button is essential when the main control or master switch is out of reach or inaccessible during a crisis.

Typically coated in bright red for visibility, the emergency stop push button is designed to be easily spotted and activated in any critical scenario. By pressing the button, the control circuit within the machinery is broken, instantly cutting off the electrical supply. This immediate shutdown ensures that the machinery ceases operation right away, allowing for a rapid response to prevent accidents and mitigate potential damage.

Engineered for swift, reliable activation, emergency stop push buttons are often wired directly into the control circuits of industrial or marine equipment. This wiring configuration guarantees the minimum response time, enabling immediate shutdown and ensuring enhanced safety for both operators and equipment.

Emergency stop push buttons are also designed for effortless operation, typically featuring intuitive handling so they can be activated quickly by any operator, minimizing response time when it matters most.

Why Are Emergency Stop Push Buttons Used?

Emergency stop push buttons are essential safety devices in industrial and marine environments, serving as immediate shutoff mechanisms for both the protection of operators and the preservation of machinery. These buttons act as preventive tools and fail-safe control switches, minimizing the risks of workplace injuries and equipment damage. Here are the primary reasons why emergency stop push buttons are widely used:

1. Avoiding Injuries

Heavy-duty machinery poses significant risks to operators, especially in fast-paced industrial settings. An emergency stop push button provides a quick and effective way to stop machinery when a worker is in danger, such as if someone accidentally moves into the path of an active machine. By pressing the emergency stop button, operators can instantly cut off power to the equipment, halting movement and minimizing the risk of injury or fatality. This rapid response capability is critical to safeguarding personnel and ensuring a safe working environment.

2. Preventing Machine Malfunction

In addition to protecting workers, emergency stop push buttons play an important role in preventing damage to machinery. If a machine begins to malfunction or display unusual behavior, an immediate shutdown may be necessary to prevent further issues. Using the emergency stop button in these situations allows operators to cut power instantly, helping to avoid potential damage, costly repairs, or replacements. This preventative measure not only protects valuable equipment but also minimizes downtime, ensuring operational continuity and safety.

Types of Emergency Stop Switches

Emergency stop switches are critical components in industrial safety systems, designed to halt machinery or processes instantly during emergencies. There are three main types of emergency stop switches, each with a unique reset mechanism and purpose to suit different industrial needs.

1. Push-Pull Emergency Stop Switch

The push-pull emergency stop switch is one of the most common types, easily recognized by its large red mushroom-shaped button. This design ensures the button is highly visible and accessible, enabling quick activation in an emergency. When the button is pressed, it immediately latches into the “stop” position, cutting off the power supply to the machinery or industrial process. To reset the switch, the operator simply pulls it back to its original position, restoring the power connection and allowing operations to resume.

2. Twist Release Emergency Stop Switch

Another widely used type is the twist-release emergency stop switch. Like the push-pull switch, it is activated by pressing the button to stop machinery instantly. However, to reset this type of switch, operators must twist the button clockwise to release it from its locked position. This twist mechanism prevents accidental resets, ensuring the machinery cannot restart until the operator intentionally resets it.

3. Key Release Emergency Stop Switch

The key release emergency stop switch adds an extra level of security by requiring a key to reset the switch. Like the other types, it activates by pressing the button, immediately stopping the machinery or process. However, only an authorized operator with the correct key can reset the switch and restart operations. This feature is particularly useful in environments where controlled access to machinery operation is critical.

Each type of emergency stop switch offers distinct advantages, allowing industries to select the most appropriate option based on their specific safety needs and operational requirements.

How Does an Emergency Stop Button Work?

An emergency stop button is a vital safety component in industrial and marine machinery, designed to immediately stop equipment and protect both operators and machinery from harm. These buttons are typically wired in series within the machinery’s control circuit, ensuring that any activation breaks the circuit and halts the power supply.

Step-by-Step Operation of an Emergency Stop Button

- Circuit Interruption

When an emergency stop button is pressed, it breaks the electrical connection within the control circuit, immediately cutting off power to the machinery. This interruption forces the equipment to stop operating, providing a rapid response to emergency situations. - Maintained Stop Position

Once pressed, the emergency stop button remains in a locked, “stop” position, preventing accidental or unintended reconnection of power until the button is manually reset. - Resetting the Button

To restart the machinery, the emergency stop button must be reset. The reset mechanism depends on the specific type of emergency stop button:- Push-Pull: The button is reset by simply pulling it back to its original position.

- Twist Release: The button is unlocked by twisting it clockwise.

- Key Release: A key is required to release and reset the button.

This reset function adds an additional layer of safety, ensuring that machinery cannot resume operation without intentional action by the operator, thus minimizing risks and enhancing overall safety in high-risk environments.

FAQs on Emergency Stop Push Button

Q1. What are the two main requirements for an emergency stop button?

A: An emergency stop button must have a direct opening mechanism on the NC (normally closed) contact and a self-holding function to stay in the “stop” position until reset.

Q2. How does an emergency stop button differ from a regular stop button?

A: An emergency stop button is used for urgent, unexpected shutdowns, while a regular stop button is used for routine stopping after normal operations.

Q3. Are emergency stop buttons normally open or closed?

A: Emergency stop buttons are normally closed; they break the circuit when pressed.

Q4. What happens immediately after pressing the emergency stop button?

A: Pressing the button cuts off power to the machinery immediately, ensuring a safe shutdown.

Conclusion

In industrial and marine environments, the emergency stop push button is an indispensable safety feature, ensuring that machinery can be quickly halted in critical situations to protect both operators and equipment. Whether you’re using a push-pull, twist-release, or key-release type, the functionality remains the same: an immediate shutdown that cuts power to prevent accidents and equipment damage. Understanding how these buttons work and why they are vital can help improve safety protocols and reduce workplace hazards. By implementing the right emergency stop system, businesses can ensure a safer working environment for their employees and enhance the longevity of their machinery.