Fuel Shut Off Solenoid

A fuel shut off solenoid is a crucial component in marine diesel engine management systems, ensuring precise control over fuel flow to the engine. In the demanding marine environment, where reliability and safety are paramount, the solenoid’s role in managing fuel supply is indispensable. By opening and closing the fuel line with precision, it helps prevent flooding during shutdowns and enables efficient start-ups, both essential for optimal performance at sea.

In this post, we’ll explore how fuel shut off solenoids work specifically in marine diesel engines, diving into their unique operating mechanisms, benefits, and the critical maintenance they require to withstand marine conditions. We’ll cover how the solenoid’s function supports engine safety and longevity, from preventing fuel wastage to safeguarding against potential malfunctions. You’ll also find helpful tips for identifying common solenoid issues and performing preventive maintenance to keep your marine diesel engine in top shape. By the end, you’ll understand why the fuel shut off solenoid is a key player in maintaining reliable and efficient marine operations.

What is a Fuel Shut Off Solenoid?

A fuel shut off solenoid is an electrically controlled device that regulates fuel flow to an internal combustion engine. By opening or closing the fuel valve, this component allows or restricts fuel from entering the engine, playing a critical role in engine start-up and shutdown procedures. Its quick response and automatic operation make it essential in various engine types, especially in diesel engines, where precise fuel control is necessary for reliable performance.

Role in Diesel Engines

In diesel engines, the fuel shut off solenoid helps manage fuel flow, ensuring that fuel is delivered only when required. This controlled fuel supply prevents fuel wastage, helps maintain fuel efficiency, and reduces the risk of flooding the engine during shutdowns. The solenoid’s reliability is particularly valued in heavy-duty and marine diesel applications, where uninterrupted operation is crucial.

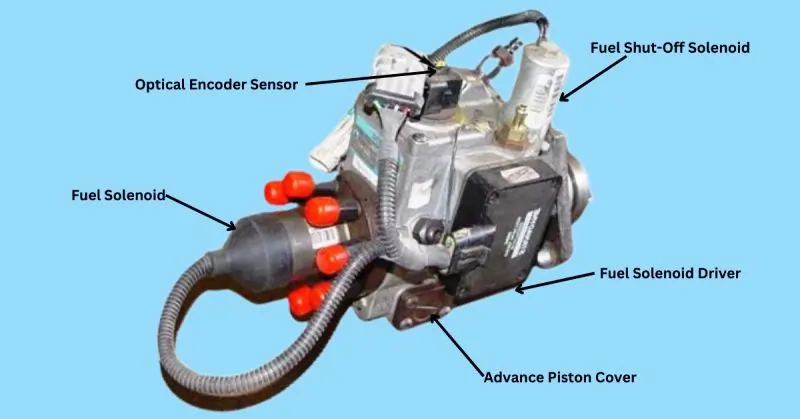

Basic Components of a Fuel Shut Off Solenoid

The fuel shut off solenoid consists of several essential components that work together to control the flow of fuel in an engine. Each part plays a specific role in the solenoid’s operation, ensuring that fuel is delivered precisely when needed and shut off to prevent flooding during shutdown.

1. Valve Body

The valve body serves as the main structure of the fuel shut off solenoid. It houses the solenoid assembly and other internal components, providing a secure enclosure that allows the device to withstand the engine’s operational demands. The valve body is designed to contain and guide fuel flow efficiently, ensuring that fuel reaches the engine only when permitted.

2. Solenoid Assembly

The solenoid assembly is the core of the device and functions as an electromagnet. When energized, it generates a magnetic field that creates a pulling force on the plunger. This magnetic action allows the valve to open and release fuel into the engine system. When the solenoid is de-energized, the magnetic field dissipates, enabling the spring to push the plunger back to its seated position, cutting off fuel flow.

3. Valve Stem

The valve stem is connected to the solenoid assembly and enables the mechanical movement necessary for opening and closing the fuel valve. It operates in sync with the solenoid’s magnetic pull, ensuring that fuel flow can be accurately controlled based on whether the solenoid is powered or unpowered.

4. Plunger

The plunger is a movable piece within the solenoid assembly that directly blocks or allows fuel flow. When the solenoid is activated, the magnetic force moves the plunger, lifting it off its seat and opening the valve. Upon deactivation, the plunger returns to its original position, blocking fuel and effectively shutting off the flow. This component is crucial in regulating fuel access to the engine, enabling smooth start-ups and secure shutdowns.

Each of these components works in unison to ensure reliable control over fuel flow, making the fuel shut off solenoid an indispensable part of modern engine management systems.

How Does a Fuel Shut Off Solenoid Work?

A fuel shut off solenoid is an electromagnetically operated valve designed to control the flow of fuel in an engine, enabling remote fuel shut-off and enhancing engine management systems. The device consists of a valve body, solenoid assembly, valve stem, and plunger, all working together to ensure fuel reaches the engine only when needed.

1. Energizing the Solenoid: Allowing Fuel Flow

When the fuel shut off solenoid is energized, an electromagnetic field is created within the solenoid assembly. This magnetic field pulls the plunger, causing it to retract and lift the spring-loaded poppet valve off its seat. With the poppet retracted, the fuel can pass through the valve, allowing fuel flow to the engine. This process is crucial for starting the engine, as it provides the initial fuel supply required for ignition.

2. Deactivating the Solenoid: Cutting Off Fuel Flow

When the solenoid is deactivated, the electromagnetic field disappears, releasing the plunger. The valve’s spring then pushes the poppet valve back into its seat, effectively blocking the fuel flow to the engine. This action ensures the engine is not flooded with fuel when it’s not running and is especially important for safety during shutdowns.

3. Manual or Automated Activation

The fuel shut off solenoid can be activated either manually or automatically, depending on the engine system. This flexibility allows for greater control, making the solenoid an essential component in ensuring safe and efficient engine operations, especially in diesel engines where precise fuel management is critical.

Why Fuel Shut Off Solenoids Are Essential in Engine Management Systems

Fuel shut off solenoids play a crucial role in modern engine management systems, contributing significantly to fuel control, safety, and engine longevity. Below are the key reasons these components are essential in managing and optimizing engine performance.

1. Preventing Fuel Leakage and Ensuring Precise Fuel Supply Control

One of the primary functions of a fuel shut off solenoid is to provide precise control over the fuel supply. By regulating fuel flow, the solenoid helps prevent unwanted fuel leakage when the engine is off. This level of control minimizes fuel wastage, improves efficiency, and reduces the risk of fuel spills, which are especially important in environments like marine applications.

2. Enhancing Engine Safety and Preventing Accidental Starts

Fuel shut off solenoids also serve as a safety feature by preventing accidental starts. When the solenoid is deactivated, fuel flow to the engine is completely blocked, ensuring that the engine cannot start unexpectedly. This is essential for marine and industrial engines, where unintentional engine operation could lead to hazardous situations.

3. Reducing Engine Wear by Providing a Clean Shut-Off Mechanism

The clean, precise shut-off provided by fuel shut off solenoids reduces engine wear. By stopping fuel flow cleanly and instantly, the solenoid helps prevent issues related to fuel flooding or excessive fuel in the system, which can cause damage over time. This controlled shut-off mechanism ultimately helps extend the engine’s lifespan by reducing unnecessary stress on internal components.

Types of Fuel Shut Off Solenoids and Their Applications in Marine Engines

Fuel shut off solenoids play an essential role in marine engine management, providing control over fuel flow in challenging environments. In marine applications, reliability, safety, and efficiency are key, making the choice of solenoid type critical to ensure smooth and secure engine operation. Here’s an overview of the main types of fuel shut off solenoids used in marine engines and their specific applications.

1. Normally Open (NO) Fuel Shut Off Solenoids

In normally open fuel shut off solenoids, the default position allows fuel to flow freely when the solenoid is not energized. This type is especially useful in marine emergency systems, where fuel flow must continue during a power loss to support critical engine functions. For example, if an electrical issue occurs onboard, these solenoids ensure that essential fuel flow remains uninterrupted, enabling emergency generators or backup propulsion systems to keep running.

2. Normally Closed (NC) Fuel Shut Off Solenoids

Normally closed fuel shut off solenoids, by default, block fuel flow when not energized. In marine engines, they are often preferred for their fail-safe design, as they prevent fuel from reaching the engine unless the system is actively powered. This is crucial for safety, as it minimizes the risk of accidental fuel flow and potential fire hazards during maintenance or idle periods. Normally closed solenoids are commonly found in primary marine engines, where precise control over fuel flow is vital.

How to Troubleshoot the Fuel Shut-Off Solenoid if it Fails to Work

To troubleshoot a fuel shut-off solenoid that isn’t working, follow these systematic steps to identify and address common issues. This table outlines the key steps for checking connections, verifying signals, and inspecting components to ensure the solenoid functions properly in controlling fuel flow to the engine.

| Step | Description | Tools Needed |

|---|---|---|

| 1. Check the Power Connection | Ensure that all wires to the fuel shut-off solenoid are securely connected and free from damage or corrosion. Use a multimeter to confirm the solenoid is receiving correct voltage. | Multimeter |

| 2. Verify the Control Signal | Use an oscilloscope or voltmeter to inspect the control signal. Confirm the voltage and waveform are within normal range, indicating proper signal flow to the solenoid. | Oscilloscope or multipurpose voltmeter |

| 3. Inspect Electromagnet and Spool | Examine the electromagnet for correct magnetic field generation when energized. Check the spool for any blockages or damage that could affect movement. | None (visual inspection) |

| 4. Test Solenoid Activation | Manually activate the solenoid if possible. If it does not respond, check the internal coil and connections for further issues. | Manual testing or specific tools as required |

| 5. Replace or Repair Components | If testing reveals any faulty components, replace or repair them to restore solenoid functionality. | Replacement parts as necessary |

Maintenance Tips for Fuel Shut Off Solenoids

Proper maintenance of fuel shut off solenoids is essential to ensure their longevity and effective operation in controlling fuel flow within an engine. Here are some key maintenance tips to keep your solenoid functioning reliably:

1. Regular Inspection of Electrical Connections and Wires

Periodically inspect the solenoid’s electrical connections and wires to ensure they are secure and free from corrosion or wear. Loose or damaged wires can interrupt power supply, leading to solenoid malfunction. Checking these components regularly helps prevent unexpected breakdowns.

2. Clean the Solenoid Valve to Prevent Clogging

Clean the solenoid valve routinely to avoid clogs from dirt, fuel residue, or debris. Build-up inside the valve can restrict fuel flow and reduce the solenoid’s efficiency. Use a gentle solvent suitable for engine components to carefully clean the valve, ensuring smooth operation.

3. Replace Worn-Out Components

Over time, the solenoid’s plunger and valve spring may wear out, affecting its performance. Replace these parts as needed to maintain proper fuel control. Regular inspection of these internal components allows for timely replacement, preventing more significant issues down the line.

4. Use Compatible Parts for Replacement

When replacing any solenoid parts, make sure they are compatible with the specific model and type. Using the right parts is crucial for optimal solenoid function and durability, helping to avoid premature wear and ensure long-lasting performance.

Pros and Cons of Using a Fuel Shut Off Solenoid

Fuel shut off solenoids offer significant benefits in engine management, particularly in controlling fuel flow and enhancing safety. However, like any component, they also come with some drawbacks. Below is a table summarizing the pros and cons of using a fuel shut off solenoid.

| Pros | Cons |

|---|---|

| Improved Safety | Potential for electrical issues or malfunctions if not properly maintained. |

| Enhanced Fuel Efficiency | Initial installation cost can be higher compared to manual shut-off valves. |

| Reduced Engine Wear | Requires regular maintenance to ensure reliable operation. |

| Automatic Fuel Control |

When to Consider Replacing Your Fuel Shut Off Solenoid

A fuel shut off solenoid is critical to the efficient operation of an engine, especially in diesel and marine applications. If the solenoid begins to fail, it can lead to significant engine problems. Below is a table outlining the signs of a failing solenoid, steps to diagnose the issue, and tips for finding the right replacement solenoid.

| Signs of a Failing Solenoid | Steps to Diagnose Whether Replacement is Necessary | Tips on Finding the Right Replacement Solenoid |

|---|---|---|

| Intermittent Engine Stalling: The engine may stall unexpectedly, especially during shutdown or startup. | 1. Inspect the electrical connections and wiring for damage or corrosion. | 1. Ensure the solenoid is compatible with your engine’s make, model, and fuel system specifications. |

| Slow or Incomplete Shutdown: The engine may take longer to shut down, or fuel flow may not stop immediately. | 2. Test the solenoid’s voltage and control signal using a multimeter or oscilloscope. | 2. Consider manufacturer recommendations for replacement solenoids to ensure quality and reliability. |

| Engine Running Rough: If the solenoid is malfunctioning, the engine may run unevenly or erratically. | 3. Check the solenoid’s internal components (e.g., plunger, spring) for wear or damage. | 3. Consult the engine’s user manual for specifications or consult a mechanic for the best fit. |

| Visible Wear or Damage: Look for signs of physical damage to the solenoid or its housing. | 4. If troubleshooting steps do not resolve the issue, consider replacing the solenoid to prevent further damage. | 4. Always replace solenoids with high-quality parts to avoid future failures and maintain engine performance. |

FAQ: Fuel Shut Off Solenoid

Q. What does a fuel shut off solenoid do?

Ans. It controls and manages the fuel flow to the engine.

Q. What is the purpose of the fuel shut-off valve?

Ans. It blocks the fuel before it reaches the engine, preventing overheating or damage.

Q. How do I know if my fuel solenoid is working?

Ans. If you hear a clicking sound, the solenoid is likely engaging properly.

Q. How does a solenoid stop working?

Ans. A solenoid can stop working if its coil overheats or short circuits, often due to high temperatures or incorrect voltage.

Conclusion

In summary, the fuel shut off solenoid is an essential component in ensuring the smooth and safe operation of diesel and marine engines. By controlling the fuel flow, it prevents flooding, enhances safety, and improves fuel efficiency, all while reducing engine wear. Regular maintenance and timely troubleshooting can help keep the solenoid functioning properly, preventing costly repairs and ensuring reliable engine performance.

Understanding how it works, recognizing when it needs attention, and choosing the right replacement are key to maintaining optimal engine operation. Whether you’re a marine operator or a diesel engine owner, taking the time to care for your fuel shut off solenoid will pay off in the form of a safer, more efficient engine that runs smoothly for years to come.