Overspeed Trip in Generator

Why Overspeed Protection is Crucial for Generators

In the ever-evolving landscape of modern power systems, ensuring the safe and efficient operation of generators is more critical than ever. One of the most significant threats to a generator’s integrity is overspeed—a condition where the generator’s rotor spins beyond its design limits, leading to potential damage, system failure, and even catastrophic accidents. Addressing this issue is not just a technical necessity but a cornerstone of operational safety and reliability.

As we move into the subject, the importance of overspeed protection becomes even more pronounced. With increasing reliance on renewable energy sources, fluctuating grid demands, and advancements in generator technology, maintaining precise control over generator speeds is essential for seamless operation. Overspeed protection systems, both mechanical and electronic, play a pivotal role in mitigating risks, ensuring longevity, and optimizing performance.

In this blog, we’ll explore the critical aspects of generator overspeed: what it is, the common causes behind it, and the potential damage it can inflict. We’ll also discuss the advanced methods available for preventing overspeed, including mechanical and electronic trip systems, and practical solutions to address overspeed when it occurs. Whether you’re a technician, an engineer, or simply someone interested in power systems, this comprehensive guide will provide valuable insights into safeguarding your generator for the demands of 2025 and beyond.

What is Generator Overspeed?

Generator overspeed occurs when the rotor of a generator spins beyond its designed speed limits. This condition can arise due to various factors, such as malfunctioning control systems, unexpected load drops, or mechanical failures. It is a critical operational issue that can compromise the safety, efficiency, and longevity of a generator.

Key Risks of Generator Overspeed

Overspeed can lead to several severe consequences, including:

- Mechanical Damage

- Excessive rotor speed generates centrifugal forces that can damage or deform key components like blades, bearings, and shafts.

- Operational Hazards

- Overspeed can destabilize the generator, leading to erratic power output, grid disruptions, or even a complete system shutdown.

- Safety Concerns

- Unchecked overspeed may result in catastrophic equipment failures, endangering personnel and surrounding infrastructure.

The Importance of Speed Regulation

Maintaining precise control of a generator’s speed is essential to prevent overspeed. Speed regulation systems, such as governors and electronic controllers, ensure the rotor operates within its safe limits. Effective speed regulation not only protects the generator from damage but also ensures consistent power delivery and operational reliability.

By addressing overspeed proactively, operators can safeguard their equipment, reduce downtime, and enhance overall system efficiency. In the following sections, we will delve deeper into the causes, prevention methods, and solutions for generator overspeed.

What Causes Generator Overspeeding?

Generator overspeeding is a critical issue caused by a variety of factors, each of which can lead to serious operational and safety risks. The main causes are described in detail below:

a. Loss or Changes to a Generator’s Speed Regulation

Speed regulation systems are designed to maintain the rotor’s speed within safe operating limits. These systems, such as mechanical governors or electronic controllers, play a crucial role in stabilizing the generator’s performance.

- Common Causes of Regulatory Failure:

- Governor Malfunctions: Mechanical or electronic faults in the governor can result in improper speed control.

- Load Mismatches: Abrupt changes in load, such as sudden disconnections, can lead to speed surges that exceed the generator’s capabilities.

When speed regulation systems fail, the generator loses its ability to adjust to fluctuating operational demands, increasing the risk of overspeed.

b. Additional Fuel Entering the Combustion Chamber

An excessive supply of fuel to the combustion chamber can cause the rotor to accelerate uncontrollably, leading to overspeed.

- Typical Situations Causing Fuel Oversupply:

- Faulty Fuel Valves: Valves that remain stuck in the open position can flood the system with excess fuel.

- Operator Errors: Mistakes in manual adjustments or miscalibrated systems can result in overfueling.

Excess fuel not only destabilizes the generator but also increases the likelihood of mechanical and thermal damage.

c. Damage to Other Components

Physical damage or wear to critical generator parts, such as turbine blades or shafts, can also lead to overspeed.

- Examples of Cascading Failures:

- Damaged Blades: A fractured turbine blade can disrupt the balance, causing the rotor to spin faster.

- Bearing Wear: Worn-out bearings can reduce resistance, inadvertently allowing the rotor to exceed its speed limits.

Such damage often triggers a chain reaction, further weakening other components and exacerbating the overspeed condition.

How to Prevent Overspeed

Preventing generator overspeed is vital to maintaining operational safety and efficiency. Modern systems use both mechanical and electronic mechanisms to mitigate overspeed risks effectively.

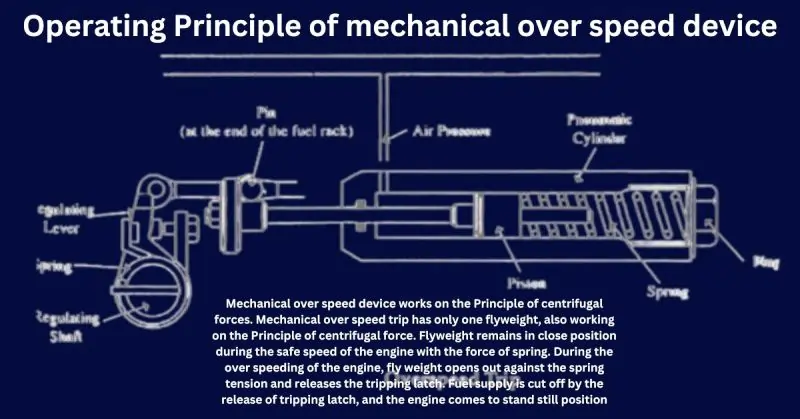

a. Mechanical Overspeed Trip

What is a Mechanical Overspeed Trip?

A mechanical overspeed trip is a device that physically intervenes when the rotor exceeds its speed limits.

How It Works:

- Operates through centrifugal force.

- Activates mechanical components, such as spring-loaded mechanisms or flyweights, to either disconnect the generator or apply braking.

Pros and Cons of Mechanical Overspeed Trips:

| Pros | Cons |

|---|---|

| Simple and reliable design. | Limited flexibility for adjustments. |

| Operates independently of power. | Requires regular maintenance. |

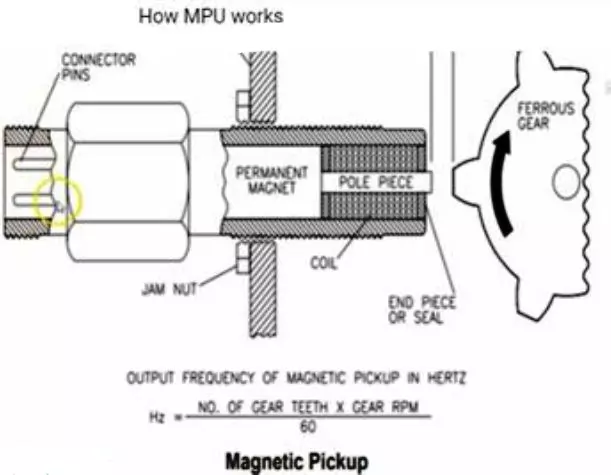

b. Electronic Overspeed Trip

What is an Electronic Overspeed Trip?

Electronic overspeed trips use advanced sensors and automation to detect overspeed and respond rapidly to prevent damage.

How It Works:

- Sensors monitor rotor speed in real-time.

- When speed exceeds safe limits, the system automatically activates to slow the rotor or shut down the generator.

Pros and Cons of Electronic Overspeed Trips:

| Pros | Cons |

|---|---|

| High precision in speed detection. | Reliant on power and electronics. |

| Easily adjustable trip thresholds. | May require complex installation. |

| Faster response times than mechanical systems. | Maintenance of sensors and software is essential. |

By combining these two methods, power systems achieve optimal protection against overspeed, ensuring reliability and safety.

The Magnetic Speed Pickup (MPU)

How to Fix Generator Overspeeding

Addressing generator overspeeding promptly is critical to prevent damage and restore safe operation. Below is a step-by-step guide to diagnosing and resolving overspeed issues effectively:

1. Diagnose the Cause of Overspeed

- Inspect the Speed Regulator:

- Check for faults or malfunctions in the speed regulation system, including mechanical governors or electronic controllers.

- Ensure calibration and responsiveness are within design specifications.

- Examine the Fuel System:

- Inspect fuel valves for leaks or malfunctions that might result in excessive fuel entering the combustion chamber.

- Check fuel delivery settings and repair any damaged components.

- Look for Physical Damage:

- Inspect critical parts like turbine blades, rotors, and bearings for wear or deformation that could destabilize speed.

- Address cascading failures caused by damaged components.

2. Implement Necessary Repairs or Adjustments

- Replace or recalibrate faulty speed regulators to restore proper speed control.

- Repair or replace damaged fuel system components to prevent further fuel oversupply.

- Fix or replace any physically damaged parts, such as rotors or bearings, to ensure mechanical stability.

3. Perform a System-Wide Test

- After repairs, conduct a comprehensive test to ensure all systems function within safe parameters.

- Monitor the generator under load to verify that speed remains within specified limits.

4. Prioritize Professional Servicing and Maintenance

Routine professional servicing is essential to prevent future overspeed issues. Trained technicians can identify potential problems early and ensure the generator operates reliably. A proactive maintenance plan minimizes risks and extends the lifespan of the generator.

How to Test the Overspeed Trip of a Generator

Testing the overspeed trip of a generator is essential for ensuring the safety and reliability of the system. This procedure verifies that the overspeed protection mechanism activates correctly under extreme speed conditions. Below is a detailed, step-by-step guide to conducting this test.

1. Preparation and Safety Precautions

- Understand System Parameters:

- Review the generator’s manual to understand the rated speed and overspeed trip settings.

- Familiarize yourself with the specific type of overspeed trip mechanism (mechanical or electronic).

- Ensure a Safe Environment:

- Perform the test in a controlled environment with no load connected to the generator.

- Ensure all personnel are at a safe distance and wearing appropriate protective gear.

2. Testing Procedure

- Step 1: Operate at Rated Speed

- Start the generator and let it run at its rated speed. Confirm that it is stable and performing as expected.

- Step 2: Adjust the Overspeed Setting Down

- Gradually lower the overspeed trip setting using the adjustment controls until the generator trips.

- Note the speed (RPM) at which the trip occurs and verify that it matches the expected threshold.

- Step 3: Restore the Overspeed Setting

- Once the trip test is complete, reset the overspeed trip mechanism to its original setting.

- Restart the generator and ensure it operates normally at rated speed.

3. Alternative Method: Testing at Actual Trip Point

- Step 1: Gradually Increase Engine Speed

- Instead of adjusting the overspeed setting, carefully increase the engine speed (RPM) beyond the rated speed.

- Monitor the RPM closely to avoid exceeding safe limits.

- Step 2: Observe the Trip Activation

- Note the exact RPM at which the overspeed trip activates. Verify that it corresponds to the designated trip point.

4. Post-Test Verification

- Inspect the System:

- Check all components of the overspeed trip mechanism for proper operation.

- Ensure no damage or misalignment occurred during the test.

- Record Results:

- Document the trip point and any observations during the test. This helps in future maintenance and compliance checks.

5. Importance of Regular Testing

Regular testing of the overspeed trip system ensures its functionality and reliability. It is an essential part of generator maintenance, safeguarding against potential overspeed incidents that could result in severe mechanical damage or safety risks. Always abide by the manufacturer’s instructions, and if necessary, get expert help.

FAQs: Overspeed Trip in Generator

Q: What causes overspeed in generators?

A: Overspeed happens when extra fuel enters the combustion chamber, causing the rotor to spin too fast.

Q: Why does an overspeed trip occur?

A: An overspeed trip happens when a shift in the balance point triggers a mechanism to release a valve, causing a loss of pressure in the trip oil header.

Q: How can I test the overspeed trip of a generator?

A: Run the generator at its rated speed, lower the overspeed setting until it trips, then reset it to the original setting.

Q: What speed do generators usually run at?

A: Small generators run at 3600 rpm (2-pole). Larger ones may run at 1200 rpm (6-pole), 900 rpm (8-pole), or 720 rpm (10-pole). For 50 Hz systems, speeds are slightly lower, like 3000 rpm for 2-pole.

Conclusion

Generator overspeed is a critical issue that poses serious risks to both equipment and personnel. Understanding its causes, such as faulty speed regulation, excess fuel supply, or damaged components, is the first step toward prevention. Implementing robust safety measures, including mechanical and electronic overspeed trips, ensures reliable protection against these risks.

By regularly testing and maintaining overspeed protection systems, you can enhance operational efficiency, prevent costly downtime, and safeguard your investment. As technology advances, incorporating automated solutions and professional servicing will play an even greater role in ensuring the safety and reliability of power systems in 2025 and beyond.

Prioritize overspeed prevention and protection today to keep your generators running smoothly and safely for years to come!