Overload Protection Devices

In today’s high-demand electrical environments, overload protection is crucial to safeguard systems from damage caused by excessive current. Without proper protection, critical components like motors, circuits, and equipment are vulnerable to overheating, short circuits, and even catastrophic failures, leading to costly downtime and repairs. This guide highlights 7 powerful overload protection devices designed to enhance safety, prevent system failures, and ensure optimal performance, offering reliable solutions for both residential and industrial applications.

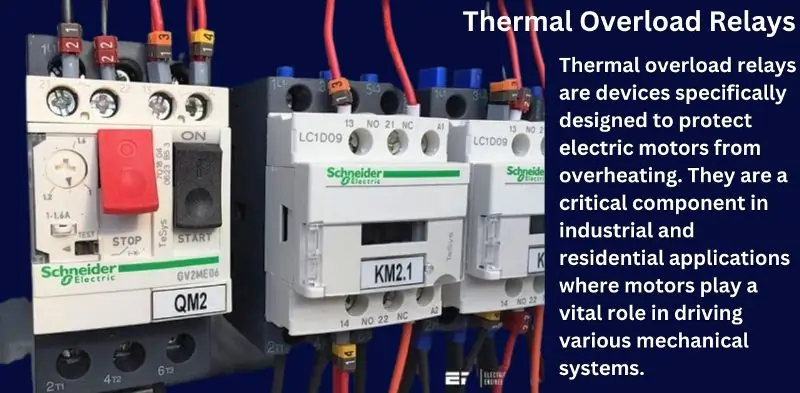

1. Thermal Overload Relays

What They Are

Thermal overload relays are devices specifically designed to protect electric motors from overheating. They are a critical component in industrial and residential applications where motors play a vital role in driving various mechanical systems.

How They Work

These relays monitor the heat generated by the motor during operation. The relay uses a bimetallic strip or other thermal sensing components to detect the temperature increase when the motor is subjected to extended overload conditions.When the temperature surpasses a preset limit, the relay triggers, cutting off the electrical circuit to prevent further heat buildup and potential motor damage.

Key Benefits

- Cost-Effective: Thermal overload relays are an affordable solution for motor protection, making them a popular choice in various industries.

- Easy Installation: These devices are simple to install and integrate seamlessly with motor control circuits.

- Reliable Protection: They provide consistent and accurate protection against overload conditions, reducing the risk of motor failure and downtime.

By incorporating thermal overload relays, you can enhance the lifespan and efficiency of your motor-driven systems while minimizing maintenance costs and unplanned interruptions.

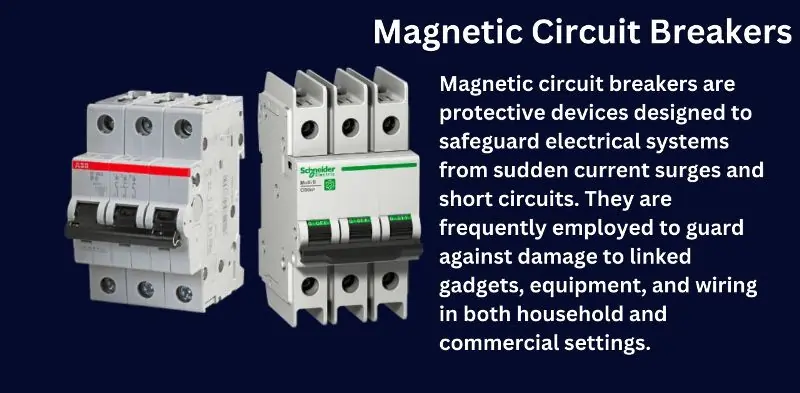

2. Magnetic Circuit Breakers

What They Are

Magnetic circuit breakers are protective devices designed to safeguard electrical systems from sudden current surges and short circuits. They are frequently employed to guard against damage to linked gadgets, equipment, and wiring in both household and commercial settings.

How They Work

These breakers operate using a magnetic coil that reacts to overcurrent conditions. When a sudden surge of electricity flows through the circuit, the magnetic field generated by the coil becomes strong enough to trip a mechanism that opens the circuit. By stopping the electricity supply, possible damage or fire risks are avoided.

Key Benefits

- Fast Response Time: Magnetic circuit breakers react almost instantaneously to overcurrent, providing immediate protection.

- Reusable: Unlike fuses, which need to be replaced after a single use, magnetic breakers can be reset and reused, making them a cost-effective option.

- Reliable Performance: They offer consistent and precise protection, ensuring the safety of your electrical systems and reducing downtime.

Incorporating magnetic circuit breakers into your electrical setup enhances safety, improves system reliability, and provides long-term protection against unexpected power surges.

3. Fuse Links

What They Are

Fuse links are one-time-use devices designed to protect electrical systems from overload and short-circuit conditions. They are a fundamental component in electrical safety, commonly used in household appliances, industrial machinery, and automotive systems.

How They Work

Fuse links consist of a calibrated metal wire or strip designed to melt when exposed to excessive current. During an overload or short circuit, the rising current heats the wire until it melts, breaking the circuit and instantly stopping the flow of electricity. This quick response protects connected devices and wiring from potential damage.

Key Benefits

- Simple Design: Fuse links have a straightforward and compact design, making them easy to install and replace.

- Low Cost: They are one of the most affordable overload protection solutions, making them an economical choice for a wide range of applications.

- Reliable Protection: Despite their simplicity, fuse links offer reliable and precise protection, ensuring safety in various electrical systems.

While fuse links require replacement after each activation, their low cost and reliability make them an essential component for protecting electrical circuits from overloads and faults.

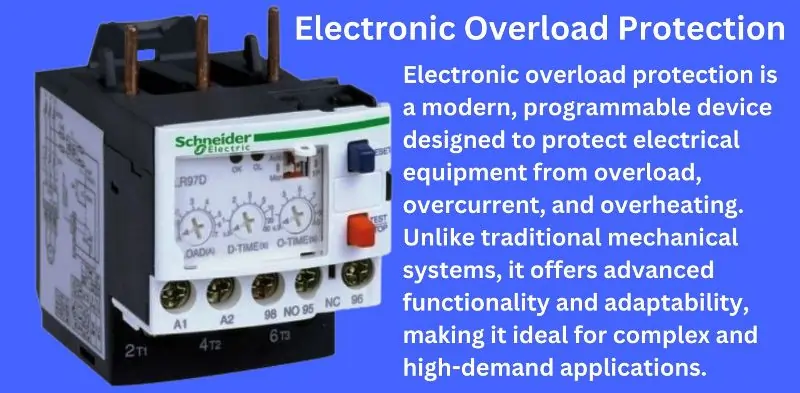

4. Electronic Overload Protection

What It Is

Electronic overload protection is a modern, programmable device designed to protect electrical equipment from overload, overcurrent, and overheating. Unlike traditional mechanical systems, it offers advanced functionality and adaptability, making it ideal for complex and high-demand applications.

How It Works

This device uses digital sensors to continuously monitor current flow and temperature in real-time. When the system detects abnormal conditions, such as excessive current or heat beyond safe limits, it automatically triggers a protective response, either by shutting down the circuit or sending alerts to operators. The system can be customized to adjust sensitivity, thresholds, and response times based on specific application requirements.

Key Benefits

- Precision: Provides highly accurate monitoring and protection, minimizing the risk of false trips and ensuring reliable system performance.

- Remote Monitoring Capabilities: Enables real-time data tracking and control through connected devices, allowing operators to monitor and manage systems remotely.

- Customizable Settings: Offers programmable features that can be tailored to meet the unique needs of different equipment and environments.

By integrating electronic overload protection, you can achieve enhanced safety, greater operational efficiency, and improved system management in both industrial and commercial settings.

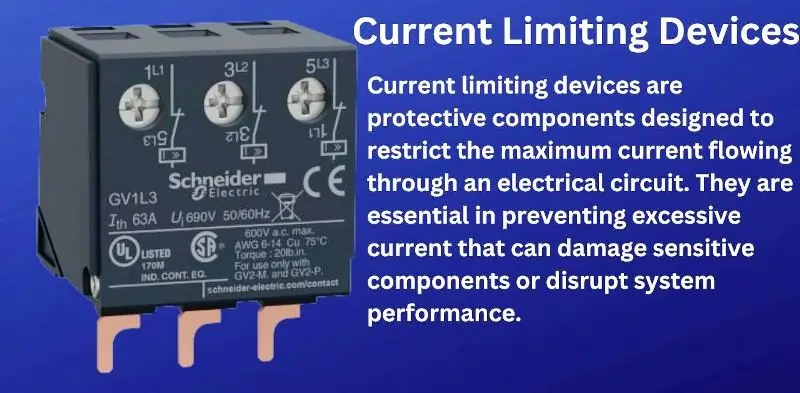

5. Current Limiting Devices

What They Are

Current limiting devices are protective components designed to restrict the maximum current flowing through an electrical circuit. They are essential in preventing excessive current that can damage sensitive components or disrupt system performance.

How They Work

These devices operate by either introducing a limiting resistance or utilizing solid-state electronics to control the current flow. In the event of a surge or overload, the device restricts the current to a safe level, ensuring that the circuit remains within its operational limits. Some advanced models dynamically adjust the current based on system conditions, providing precise protection.

Key Benefits

- Protects Sensitive Components: Prevents damage to delicate electronic components, such as semiconductors and sensors, by limiting current surges.

- Extends Equipment Life: Reduces wear and tear on electrical systems, enhancing the longevity and reliability of connected devices.

- Improves System Stability: Helps maintain consistent current flow, minimizing disruptions and ensuring smooth operation.

Incorporating current limiting devices into your electrical systems enhances protection, improves performance, and ensures the long-term durability of critical equipment.

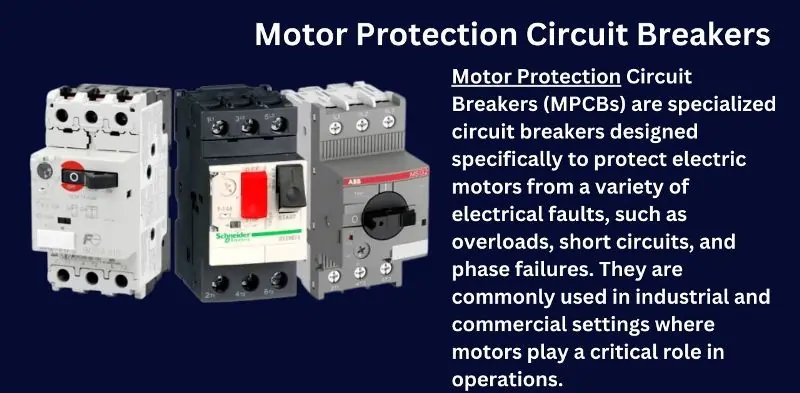

6. Motor Protection Circuit Breakers (MPCBs)

What They Are

Motor Protection Circuit Breakers (MPCBs) are specialized circuit breakers designed specifically to protect electric motors from a variety of electrical faults, such as overloads, short circuits, and phase failures. They are commonly used in industrial and commercial settings where motors play a critical role in operations.

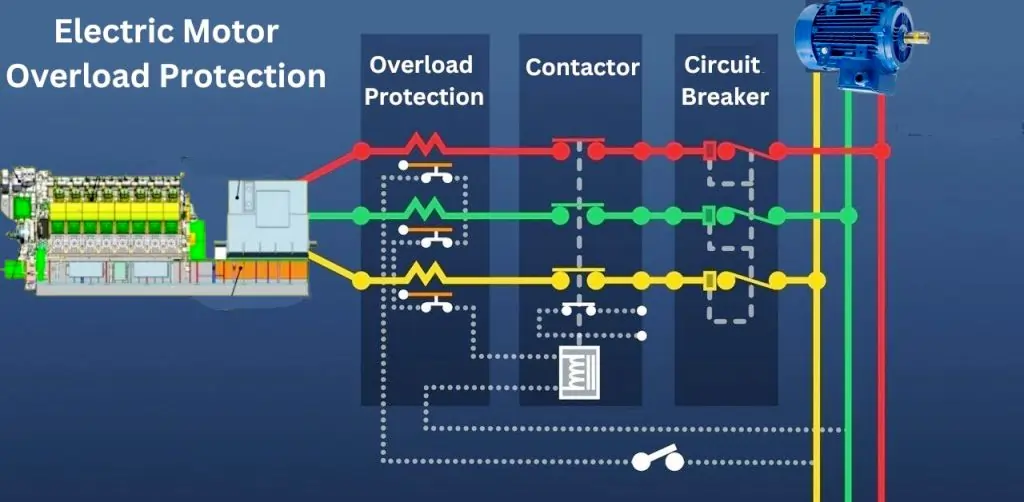

How They Work

MPCBs combine both thermal and magnetic protection mechanisms:

- Thermal Protection: Monitors the motor’s temperature and trips the circuit if the motor overheats due to prolonged overload conditions.

- Magnetic Protection: Detects short circuits or sudden current surges and instantly interrupts the circuit to prevent damage.

This dual protection system ensures that the motor is safeguarded from both gradual and sudden electrical faults.

Key Benefits

- Comprehensive Motor Safety: Provides protection against a wide range of electrical faults, ensuring the motor operates safely and efficiently.

- Adjustable Settings: Allows customization of trip settings to match the specific requirements of different motor types and applications.

- Increased Equipment Lifespan: Reduces the risk of motor damage, extending the life of both the motor and connected equipment.

- Easy Integration: Compact design and compatibility with motor control systems make MPCBs easy to install and manage.

Using MPCBs in your electrical systems ensures reliable motor protection, minimizing downtime and maintenance costs while maximizing operational efficiency.

7. Overload Protection Modules (OPMs)

What They Are

Overload Protection Modules (OPMs) are standalone or integrated devices designed to protect electrical systems from overload conditions. They can be installed as independent units or incorporated directly into equipment, making them a versatile solution for a wide range of applications.

How They Work

OPMs continuously monitor the current flowing through a circuit. When an overload condition is detected—where the current exceeds safe operating limits—the module automatically shuts off the power to prevent overheating, equipment damage, or system failure. Once the issue is resolved, many OPMs can be reset manually or automatically, restoring normal operation.

Key Benefits

- Versatile Application: Suitable for use in various electrical systems, including industrial machinery, HVAC systems, and consumer electronics.

- Enhanced Equipment Protection: Prevents damage caused by excessive current, reducing downtime and maintenance costs.

- Easy Integration: Can be easily added to existing systems or designed into new equipment for seamless protection.

By implementing Overload Protection Modules, you can ensure reliable operation, enhance safety, and protect valuable electrical assets across diverse applications.

FAQs on Overload Protection Devices

Q. What are overload protective devices?

Ans. They detect the amount of current being drawn in an electrical system.

Q. Which device is used for overload protection?

Ans. Fuses and circuit breakers are commonly used for overload protection.

Q. Why is overload protection important?

Ans. It helps prevent damage to electrical systems by controlling excessive current.

Q. What is the full form of OLR relay?

Ans. OLR stands for Overload Relay.

Conclusion

Choosing the right overload protection device is crucial for ensuring the safety and reliability of your electrical systems. Proper protection minimizes the risk of damage, improves operational efficiency, and extends the lifespan of your equipment. Take the time to assess your current systems and consider upgrading to a more reliable overload protection solution to safeguard your valuable assets and enhance performance.