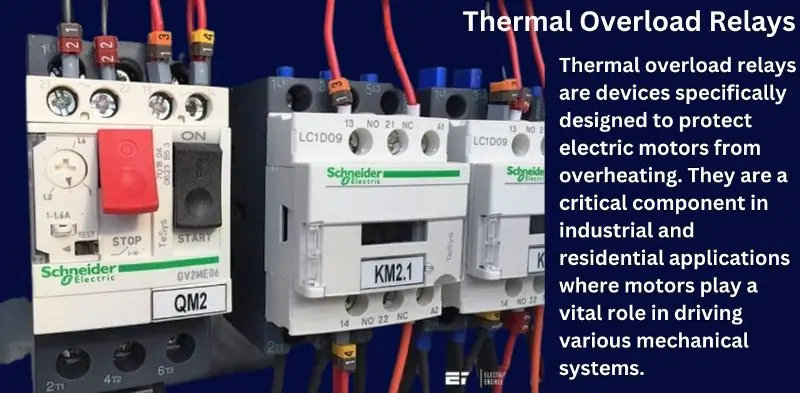

What is a Thermal Overload Relay

A thermal overload relay is a crucial component in electrical systems, designed to protect motors and circuits from overheating. By monitoring temperature levels, it prevents damage caused by excessive heat, ensuring the longevity and reliability of motors. This simple yet effective safety device helps maintain smooth operations and reduces the risk of costly repairs.

Understanding Thermal Overload Relays

What is a Thermal Overload Relay?

A thermal overload relay is a protective device used in electrical systems to prevent motors from overheating. It monitors the temperature of the motor and disconnects the power if it detects excessive heat, thereby preventing potential damage due to overcurrent or prolonged operation under heavy load.

How Do Thermal Overload Relays Work?

Thermal overload relays operate on the principle of heat generation. When a motor runs under load for an extended period, it generates heat. If the motor is exposed to excessive current or a fault, the temperature rises, which could cause the motor windings to deteriorate. The thermal overload relay senses this rise in temperature and disconnects the motor to avoid permanent damage, ensuring protection for both the motor and the entire electrical system.

Basic Components of a Thermal Overload Relay

- Bimetallic Strip: The key component in a thermal overload relay is the bimetallic strip, which consists of two different metals with varying thermal expansion rates. When the relay detects heat, the strip bends as it warms up, triggering the disconnection of the motor’s power supply.

- Reset Mechanism: After the relay has disconnected due to overheating, the reset mechanism allows the relay to be manually or automatically reset once the motor cools down. This feature prevents unnecessary downtime and allows the motor to resume operation when it’s safe.

These essential components work together to safeguard motors, enhancing their lifespan and ensuring the reliability of the electrical system.

Benefit #1: Prevents Motor Damage

How Thermal Overload Relays Protect Motors

Thermal overload relays are essential in protecting motors from running at unsafe temperatures. When motors operate under heavy load or encounter faults, they can overheat, which may lead to severe damage to the motor windings, insulation, and other critical components. The thermal overload relay continuously monitors the motor’s temperature, and if it exceeds a preset threshold, the relay disconnects the power, preventing further overheating.

The Potential for Overheating to Cause Motor Failure

Excessive heat is a primary cause of motor failure. When a motor operates beyond its intended temperature range, the insulation on the windings can deteriorate, leading to short circuits, burns, or total motor failure. Overheating also accelerates wear on bearings, increasing the risk of mechanical breakdowns. If not addressed, these issues can result in costly repairs or even the need for a full motor replacement.

Real-World Scenario

Consider an industrial factory where multiple motors drive conveyor belts. One of the motors begins to overheat due to an unbalanced load. Without a thermal overload relay, the motor continues running at unsafe temperatures, eventually causing it to fail and halt production for hours. However, with a thermal overload relay installed, the motor is automatically shut down before it overheats, preventing permanent damage and saving the company from expensive repairs and costly downtime.

Benefit #2: Increases Equipment Lifespan

How Thermal Overload Relays Extend Equipment Lifespan

Thermal overload relays play a key role in prolonging the lifespan of motors and other electrical equipment. By preventing overheating, they ensure that the motor operates within safe temperature ranges, avoiding the degradation of critical components such as insulation, bearings, and windings. Regularly protecting against heat-related stress allows the equipment to function optimally for a longer period, reducing the need for premature replacements.

Reducing Wear and Tear Caused by Overheating

When motors overheat, the constant exposure to high temperatures accelerates wear and tear on essential components. Insulation begins to break down, bearings lose their lubrication, and other parts may deform or malfunction. This lowers the motor’s efficiency over time and raises the risk of mechanical failure. A thermal overload relay helps mitigate these risks by disconnecting the power whenever the temperature exceeds safe limits, significantly reducing the wear caused by overheating.

Long-Term Cost Savings

By extending the lifespan of motors, thermal overload relays help save money in the long run. Reduced wear and tear means fewer repairs and less frequent motor replacements, leading to significant cost savings. In industries where motor-driven equipment is essential, the financial benefits of fewer replacements and repairs can be substantial, making thermal overload relays a cost-effective investment for maintaining equipment reliability over time.

Benefit #3: Reduces Maintenance Costs

How Thermal Overload Relays Reduce Expensive Repairs and Replacements

Thermal overload relays help reduce maintenance costs by preventing damage caused by overheating. By automatically disconnecting the motor when temperatures reach dangerous levels, they stop minor issues from escalating into major problems that would require expensive repairs or replacements. This proactive protection helps businesses avoid the costs associated with damaged motors, burned-out components, and other heat-related failures.

The Role of Preventive Maintenance in Lowering Operational Costs

In order to reduce downtime and guarantee equipment longevity, preventive maintenance is essential. By incorporating thermal overload relays into the system, businesses can reduce the frequency of unexpected breakdowns. Since these relays help protect against overheating, they contribute to smoother, more efficient operations, ultimately lowering overall operational costs. Fewer repairs and less downtime lead to higher productivity and reduced financial strain from emergency fixes.

Real-World Example: Saving on Repair Costs

Consider a manufacturing plant that uses thermal overload relays in their conveyor belt motors. In the past, the motors would occasionally overheat, leading to frequent breakdowns and expensive repairs. After installing thermal overload relays, the system effectively protected the motors from overheating. As a result, the plant saw a significant reduction in repair costs and maintenance calls, leading to an estimated savings of 20% annually in maintenance expenses. The relays not only protected the motors but also improved the overall efficiency of the operation.

Benefit #4: Improves Safety

How Overload Relays Prevent Dangerous Overheating Situations

Thermal overload relays play a critical role in improving safety by preventing dangerous overheating situations. When a motor runs too hot, it can cause various safety hazards, including electrical fires, equipment damage, or electrical shock risks. The relay monitors temperature and automatically disconnects the power when unsafe conditions are detected, significantly reducing the likelihood of these hazardous events.

Reducing the Risk of Fires and Electrical Hazards

Overheating is a common cause of electrical fires. If a motor continues to operate at high temperatures, the risk of ignition in surrounding materials, such as wiring insulation, increases. Thermal overload relays help mitigate this risk by cutting off the motor’s power when it reaches critical temperatures, thus reducing the chances of fires and other electrical hazards that can arise from sustained overheating.

Compliance with Safety Regulations and Standards

Many industries are required to adhere to strict safety standards to ensure the well-being of their workers and the protection of their equipment. By integrating thermal overload relays, businesses can ensure they meet these regulations, avoiding potential fines or penalties. Furthermore, these relays help maintain a safe working environment, making it easier for companies to stay compliant with safety guidelines and industry standards.

Benefit #5: Energy Efficiency

Improving Energy Efficiency by Preventing Unnecessary Power Consumption

Thermal overload relays contribute to energy efficiency by preventing motors from running at excessive temperatures, which can cause inefficient operation and unnecessary power consumption. When motors overheat, they often draw more power to maintain their performance, leading to wasted energy. By disconnecting the motor when it reaches an unsafe temperature, the thermal overload relay ensures that power is only consumed when the motor is operating efficiently, reducing overall energy usage.

Maintaining Consistent Performance and Energy Usage

By protecting motors from overheating, thermal overload relays help maintain consistent performance and prevent energy waste. With the relay in place, motors can operate within their optimal temperature range, ensuring they run smoothly and efficiently without straining the system. This consistent performance translates into more reliable energy usage, helping businesses lower their energy bills and minimize their environmental footprint.

FAQs on Thermal Overload Relays

Q. How do thermal overload relays work?

Ans. They monitor the heat produced by an electric motor during operation to prevent overheating.

Q. What is the purpose of an overload relay?

Ans. It cuts off power to the motor when there is a high current, ground fault, short circuit, phase failure, or mechanical jamming.

Q. What does a thermal overload relay provide?

Ans. It offers dependable protection for motors against overloads and phase failures.

Q. What is the principle of a thermal relay?

Ans. It works based on the heating effect caused by electric current.

Conclusion

Thermal overload relays provide key benefits, including protecting motors from damage, extending equipment lifespan, reducing maintenance costs, improving safety, and enhancing energy efficiency. Investing in these protective devices is essential for ensuring motor longevity, minimizing downtime, and maintaining system safety. By preventing overheating and other hazards, thermal overload relays help safeguard both your equipment and operations, making them a vital component of any electrical system.