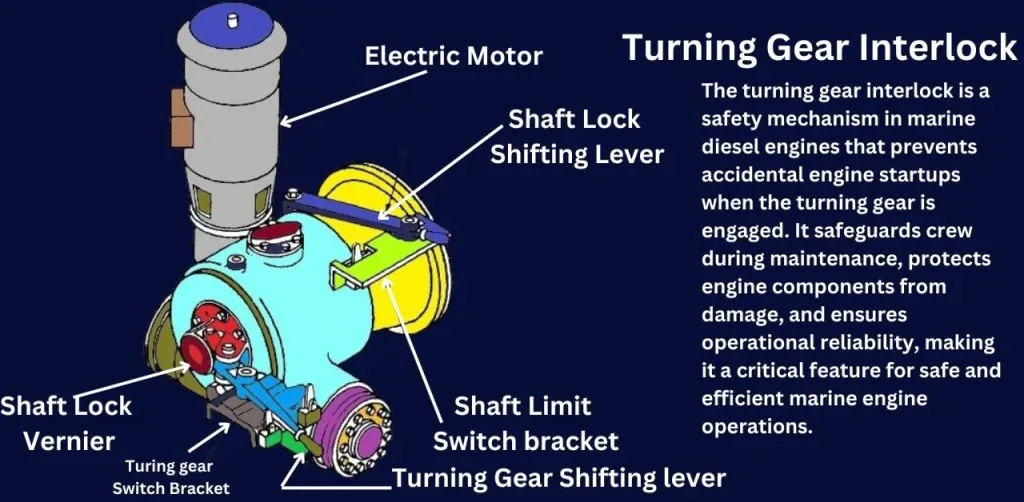

Turning Gear Interlock

In the complex world of marine diesel engines, safety and precision are paramount. One crucial component ensuring both is the turning gear interlock—a safeguard designed to prevent engine mishaps during maintenance and operation. By locking the turning gear in place, this system not only protects the engine from accidental damage but also ensures crew safety, making it an indispensable feature of modern marine engines.

In this blog, we’ll explore the top 7 powerful features of turning gear interlocks, shedding light on their functionality and impact. Whether you’re an engineer, a marine enthusiast, or someone keen on understanding critical maritime systems, this guide will equip you with valuable insights into how turning gear interlocks optimize operations and ensure smooth sailing.

Enhanced Safety Mechanism

Preventing Accidental Engine Startups

The turning gear interlock is a vital safety feature in marine diesel engines, designed to prevent accidental engine startups when the turning gear is engaged. This mechanism ensures that the engine remains stationary during maintenance or inspections, eliminating the risk of unintended rotation that could lead to catastrophic failures or injuries.

Protecting Crew and Equipment

By locking the turning gear in place, the interlock safeguards both the crew and the equipment. During routine maintenance, engineers often work in close proximity to the engine components. Any accidental movement could pose a serious threat to their safety and potentially damage critical engine parts, leading to costly repairs and operational delays.

Real-World Incidents Prevented

In numerous instances, the turning gear interlock has proven its worth by averting accidents. For example:

- Case Study 1: During a scheduled engine overhaul, the interlock prevented an accidental engine start triggered by a miscommunication on the bridge, saving the maintenance crew from harm.

- Case Study 2: On a cargo vessel, the turning gear interlock stopped an unintended crankshaft rotation, which could have damaged newly installed engine components.

Seamless Integration with Engine Systems

Integration with Marine Diesel Engine Control Systems

The turning gear interlock is meticulously designed to integrate seamlessly with the control systems of marine diesel engines. By functioning as a vital part of the engine’s operational framework, it communicates with other safety and control mechanisms, ensuring that the engine’s status is consistently monitored. This integration allows for automated checks that confirm whether the turning gear is engaged before permitting the engine to start, thus preventing operational errors.

Simplification of Operational Workflows

This integration significantly simplifies workflows on board. Operators no longer need to manually verify the position of the turning gear before starting the engine. The interlock automates this critical safety check, reducing the potential for human error and streamlining engine operation procedures.

Improved Efficiency

By automating safety checks and synchronizing with the engine control systems, the turning gear interlock enhances overall efficiency. Maintenance and operational activities become faster and safer, ensuring minimal downtime and optimal performance. This efficiency is particularly critical in marine environments, where time-sensitive operations are the norm.

In essence, the seamless integration of the turning gear interlock with marine diesel engines ensures not only safety but also smoother and more efficient engine operations.

Prevention of Engine Damage

Avoiding Damage Due to Improper Engagement

The turning gear interlock plays a crucial role in protecting marine diesel engines by preventing improper engagement of the turning gear. If the engine were to start while the turning gear is engaged, it could lead to severe mechanical damage, including bent shafts, broken gears, or compromised engine components. The interlock acts as a fail-safe, ensuring the turning gear is disengaged before the engine is allowed to start. This protection is essential for maintaining the integrity of the engine system.

Extending Engine Lifespan

By preventing such accidental damages, the turning gear interlock significantly contributes to the long-term health of the engine. It minimizes wear and tear caused by operational mishaps, ensuring that critical components operate within their designed parameters. This not only reduces the frequency of repairs but also extends the overall lifespan of the engine, leading to lower maintenance costs and improved reliability.

In summary, the turning gear interlock is an indispensable safeguard that protects marine diesel engines from avoidable damage, enhancing their durability and ensuring optimal performance over time.

Automated and Manual Control Options

Flexibility in Operation

The turning gear interlock offers a dual control system, combining automated features with manual control options. In modern marine diesel engines, the automated function ensures seamless operation, integrating with advanced engine management systems to monitor and control the interlock’s engagement. This automation simplifies routine processes, reduces human error, and enhances efficiency. At the same time, the manual control option serves as a reliable fallback, providing redundancy for situations where automation might fail or is unavailable.

Adapting to Varying Operational Scenarios

The flexibility to switch between automated and manual modes is critical in diverse marine environments. For example:

- During Routine Operations: Automated controls ensure smooth and consistent functionality, minimizing crew intervention.

- In Emergency Situations or System Failures: The manual override allows operators to maintain control, ensuring operational continuity and safety.

Ensuring Reliability in Marine Settings

This dual-mode functionality is particularly valuable in marine settings, where unpredictable conditions can arise. The ability to adapt to different scenarios enhances the reliability of the turning gear interlock, making it an indispensable component for safe and efficient engine operation.

In essence, the automated and manual control options of the turning gear interlock provide a perfect balance of modern convenience and operational reliability.

Durability and Resistance to Harsh Environments

Built for Extreme Marine Conditions

The turning gear interlock is engineered to endure the demanding conditions aboard marine vessels. Marine environments subject equipment to high levels of humidity, salt exposure, temperature fluctuations, and mechanical stress. Despite these challenges, the interlock remains reliable, ensuring uninterrupted safety and operational efficiency even in the harshest scenarios.

Material Specifications and Corrosion Resistance

The interlock components are constructed from robust materials, such as stainless steel or specially coated alloys, chosen for their strength and corrosion resistance. These materials prevent degradation from constant exposure to saltwater, high humidity, and other corrosive elements common in marine settings. Advanced coatings and finishes further enhance the longevity and durability of the system, reducing maintenance requirements and ensuring consistent performance.

Ensuring Long-Term Reliability

This exceptional durability not only minimizes wear and tear but also reduces the frequency of replacements and repairs. By maintaining its integrity over extended periods, the turning gear interlock supports the overall reliability and safety of marine diesel engines, making it a critical asset for maritime operations.

In summary, the turning gear interlock’s durability and resistance to harsh environments ensure that it performs effectively, safeguarding marine engines in the most challenging conditions.

Compliance with Maritime Regulations

Meeting International Maritime Safety Standards

Turning gear interlocks are meticulously designed to comply with global maritime safety standards such as the International Convention for the Safety of Life at Sea (SOLAS) and regulations set by the International Maritime Organization (IMO). These standards mandate safety mechanisms to prevent accidents during engine operation and maintenance, ensuring the protection of crew, equipment, and vessels. The turning gear interlock’s functionality aligns with these requirements, making it a crucial component for safe marine operations.

Importance of Regulatory Compliance

Regulatory compliance is vital for obtaining operational approvals and certifications from maritime authorities. Vessels equipped with systems adhering to international safety standards are more likely to pass inspections, reducing the risk of penalties or operational disruptions. Furthermore, compliance demonstrates a commitment to safety, enhancing the vessel’s reputation and operational credibility in the industry.

Ensuring Safe and Efficient Operations

By meeting these stringent regulations, turning gear interlocks not only enhance safety but also facilitate smooth operational processes. They provide assurance to shipowners, operators, and regulatory bodies that the vessel is equipped with reliable and compliant safety mechanisms.

In conclusion, the turning gear interlock’s adherence to maritime safety standards underscores its role as an essential safeguard for modern marine diesel engines.

Cost Efficiency and Maintenance Benefits

Reduction in Maintenance Costs

The turning gear interlock’s preventive safety features significantly reduce the likelihood of accidental engine damage, which can be costly to repair. By ensuring that the engine cannot start while the turning gear is engaged, the interlock helps avoid incidents that could lead to bent shafts, damaged gears, or other critical failures. This proactive protection minimizes the frequency of unscheduled repairs and extends the intervals between major overhauls, leading to substantial savings on maintenance costs.

Long-Term Economic Benefits

For marine operators, the turning gear interlock is not just a safety feature but a cost-effective investment. Its ability to prevent engine damage contributes to enhanced engine longevity, reducing the need for frequent replacements of expensive components. Additionally, fewer maintenance interruptions mean increased operational uptime, allowing vessels to adhere to schedules and avoid revenue losses caused by delays or downtime.

Enhanced Operational Value

The long-term economic benefits of the turning gear interlock make it a valuable asset for marine operations. By combining safety with cost efficiency, it supports the sustainability of vessel operations, ensuring both safety compliance and financial viability in the competitive maritime industry.

Practical Applications in Marine Diesel Engines

Examples of Turning Gear Interlocks in Action

Turning gear interlocks play a critical role in ensuring the safe and efficient operation of marine diesel engines. For instance:

- During routine maintenance, the interlock prevents accidental engine startups, allowing engineers to work safely on moving parts like the crankshaft or pistons.

- When performing system inspections, the interlock ensures the engine remains stationary, avoiding unintended rotation that could disrupt the inspection process.

- In troubleshooting scenarios, the interlock safeguards both personnel and equipment by preventing any inadvertent engagement of the engine.

These real-world applications showcase the interlock’s value in promoting safety and operational efficiency aboard vessels.

Role During Engine Maintenance

During engine overhauls or repairs, engineers need the engine to stay securely locked in a non-operational state. The turning gear interlock ensures this by engaging with the engine’s control system, blocking any startup attempts until the turning gear is fully disengaged. This feature is vital for preventing accidents and ensuring precise maintenance work.

Support for Inspections and Troubleshooting

The interlock is indispensable during inspections, allowing engineers to rotate the engine manually with the turning gear while ensuring no accidental starts occur. Similarly, in troubleshooting scenarios, the interlock provides a controlled environment for diagnosing issues, preventing further damage or unsafe conditions.

In summary, the turning gear interlock is a key component of marine diesel engines, ensuring safety and efficiency during maintenance, inspections, and troubleshooting activities.

FAQs on Turning Gear Interlock

Q: How does the turning gear interlock work?

A: It stops starting air from entering the engine cylinders when the turning gear is engaged.

Q: What is the turning gear in a ship?

A: It’s a motor that slowly turns a large diesel engine or turbine using gears.

Q: Why is slow turning of the main engine important?

A: It avoids damage from water or oil leaking into the engine cylinders.

Q: What is the principle of interlock?

A: It prevents accidents by stopping contact with live electrical parts.

Conclusion

In this blog, we’ve explored the 7 powerful features of turning gear interlocks, highlighting their role in enhancing safety, preventing engine damage, and ensuring smooth operations in marine diesel engines. These features, from automated and manual control options to compliance with international regulations, underscore the importance of investing in a reliable interlock system.

For marine operators, choosing a robust turning gear interlock is a key step in ensuring long-term efficiency and safety. Explore high-quality interlock solutions today to safeguard your equipment and crew while maximizing operational performance.