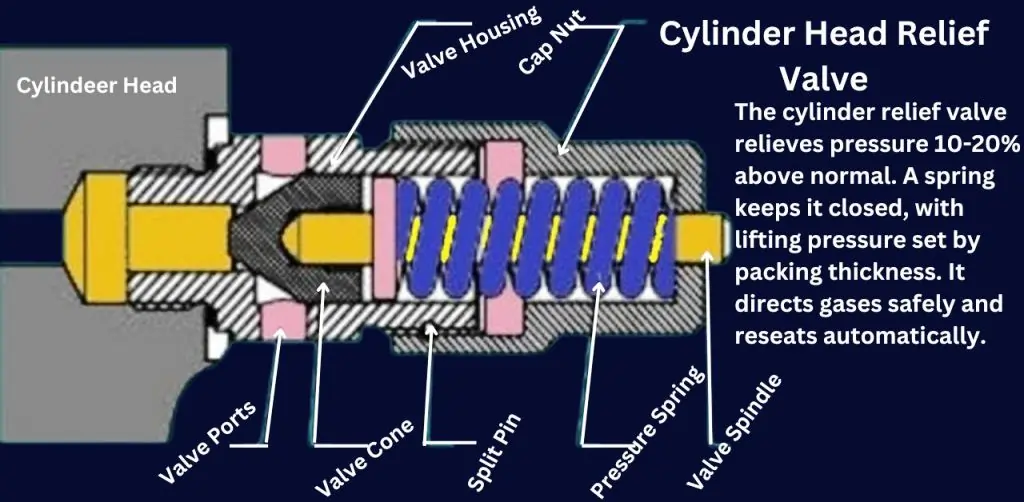

Cylinder Head Relief Valve

The cylinder head relief valve is a critical safety component in marine diesel engines, designed to protect the engine from excessive pressure buildup. Its primary role is to ensure controlled pressure release, safeguarding both the machinery and crew during operations.

In marine engines, maintaining optimal pressure is vital not just for performance but also for preventing potential hazards. The cylinder head relief valve serves as a fail-safe mechanism, stepping in when pressure exceeds safe limits.

This blog explores the five powerful features of the cylinder head relief valve, highlighting its indispensable role in ensuring safety, efficiency, and reliability in engine operations.

1. High-Pressure Relief Mechanism

The cylinder head relief valve is specifically engineered to handle pressures that exceed normal operating levels by 10-20%. This critical feature prevents dangerous pressure buildup that could lead to catastrophic engine failure.

The Role of the Spring Mechanism

A sturdy spring mechanism lies at the heart of this system.The spring keeps the valve securely closed during normal operations. When the internal pressure rises beyond the set threshold, the spring allows the valve to lift, releasing the excess pressure safely and effectively.

Protection for Engine Components

By relieving excess pressure, the valve prevents strain and damage to key engine components such as cylinder heads and pistons. This protection not only enhances the safety of the engine but also extends its operational lifespan, ensuring reliable performance over time.

2. Safe Gas Release System in Cylinder Head Relief Valve

The safe gas release system of the cylinder head relief valve is designed to direct escaping gases to a secure outlet, preventing potential hazards from pressure buildup. This system plays a vital role in maintaining engine safety and preventing catastrophic damage in high-pressure scenarios.

Importance of Proper Venting in High-Pressure Systems

In marine diesel engines, proper venting is essential to control pressure and ensure the safe operation of the engine. The cylinder head relief valve efficiently channels gases away from critical engine components, preventing dangerous conditions such as overheating, explosions, or component failure.

Real-World Effectiveness

In practice, the safe gas release system effectively protects against pressure-induced damage. For instance, during instances of pressure surges, the system safely vents gases, ensuring that the engine remains protected from excessive stress. This contributes significantly to both the longevity and reliability of the engine, preventing costly repairs and downtime.

3. Precision Lifting and Reseating

The cylinder head relief valve is equipped with a precision lifting and reseating mechanism, ensuring controlled and efficient pressure release when required. This feature is essential for maintaining safe operating conditions while minimizing the risk of valve damage.

Controlled Pressure Release

The valve is designed with a limited lift to ensure that pressure is released gradually and safely. This controlled release prevents sudden bursts of pressure that could damage engine components. The limited lift ensures the valve performs its function without over-extending or causing additional strain on the system.

Separate Valve and Spindle Mechanism

The separate valve and spindle mechanism allows for reliable reseating after the valve has been activated. This feature ensures that the valve seals properly after pressure release, preventing any leakage or malfunction. The ability to reseat securely enhances the overall functionality of the system, ensuring it operates reliably over time.

Longevity and Reliability

By controlling the lifting action and ensuring proper reseating, this design significantly extends the valve’s lifespan. It minimizes wear and tear on the valve and spindle, contributing to long-term reliability and reducing the need for frequent replacements or repairs. This precision mechanism ensures that the cylinder head relief valve consistently performs optimally, enhancing the overall efficiency and safety of the engine.

4. Customizable Lifting Pressure

One of the standout features of the cylinder head relief valve is its customizable lifting pressure, allowing for precise adjustments to suit specific engine needs. This flexibility is key to optimizing the performance and safety of marine diesel engines.

Adjusting Lifting Pressure Using Packing Piece Thickness

The lifting pressure of the valve can be fine-tuned by adjusting the thickness of the packing piece. This allows for careful calibration of the valve’s activation pressure, ensuring it opens only when required, at the exact pressure level necessary for optimal engine protection.

Flexibility to Adapt to Specific Engine Requirements

The ability to adjust the lifting pressure is especially valuable when dealing with different engine configurations or operating conditions. Whether for a high-performance engine or one subject to varying loads, the valve can be adapted to meet the specific needs of each engine, ensuring reliable operation across various scenarios.

Benefits of Customization for Different Operational Scenarios

Customizing the lifting pressure enhances the valve’s ability to respond appropriately to the unique demands of different operational environments. This not only improves the safety of the engine but also boosts efficiency, as the valve can be set to operate optimally under both routine and extreme conditions. Customization provides significant benefits in preventing damage while ensuring optimal engine performance throughout its lifecycle.

5. Robust Construction for Durability

The cylinder head relief valve is designed with robust construction to ensure long-lasting durability and reliable performance in high-pressure environments. This durable design ensures that the valve remains functional even under the harshest marine conditions, making it a key component for safe engine operation.

Materials and Design Built to Withstand High-Pressure Environments

The valve is constructed using high-quality materials specifically chosen for their ability to handle extreme pressure. The design ensures that the valve can withstand the stresses of high-pressure systems, preventing damage and maintaining operational efficiency over time.

Corrosion Resistance and Performance in Extreme Marine Conditions

Marine environments are known for their harsh conditions, including constant exposure to saltwater and fluctuating temperatures. The cylinder head relief valve is engineered to resist corrosion, ensuring that it performs consistently even in these extreme conditions. Its corrosion-resistant materials help maintain its integrity and efficiency, even in the challenging marine environment.

Long-Term Cost Efficiency Due to Minimal Maintenance Needs

Thanks to its durable construction, the cylinder head relief valve requires minimal maintenance over its lifespan, making it a cost-effective solution for marine operators. Its ability to endure high pressure and resist corrosion means fewer repairs, less downtime, and ultimately lower operational costs, providing significant long-term value.

FAQ: Cylinder Head Relief Valve

Q. What is the function of the cylinder head relief val

A. It relieves excessive crankcase pressures and prevents flames from escaping the crankcase.

Q. Where is the main engine cylinder relief valve located?

A. It is located on top of the cylinder head.

Q. What is the cylinder head in an engine?

A. The cylinder head forms the upper part of the combustion chamber, housing the spark plugs and injectors.

Q. Do gas cylinders have relief valves?

A. Yes, gas cylinders are typically protected by spring-loaded pressure-relief valves, such as Type CG-7

Conclusion

In summary, the five powerful features of the cylinder head relief valve — its high-pressure relief mechanism, safe gas release system, precision lifting and reseating, customizable lifting pressure, and robust construction — all play critical roles in maintaining engine safety, durability, and performance. These features are essential for managing pressures, preventing hazardous situations, and ensuring optimal functioning of marine diesel engines.

The cylinder head relief valve is a key component for engine safety and efficient performance, helping to protect both the engine and crew from potential dangers. Investing in a high-quality valve can significantly enhance your engine’s operational reliability, reducing maintenance costs and increasing overall safety.

Ensure the safety and longevity of your engine by choosing top-tier cylinder head relief valves — your investment in quality today will pay off with dependable performance for years to come.