Oil Mist Detector

Oil mist detection is crucial for the safety of marine engines, where continuous operation and high-performance demands increase the risk of crankcase explosions. Oil mist detectors play a vital role in safeguarding marine engines by monitoring oil mist levels within the crankcase, providing early alerts to prevent dangerous buildup that can lead to catastrophic failure.

In this post, we’ll dive into how oil mist detectors work, the technology behind their detection mechanisms, and why they are indispensable for marine engine safety. We’ll also share six essential tips for their effective use, covering installation, maintenance, calibration, and crew training to ensure reliable performance and safe voyages at sea.

Oil Mist Detector: What Is It?

An oil mist detector is a critical safety device specifically designed to monitor and detect hazardous levels of oil mist within engine crankcases. In marine engines and other large industrial engines, these detectors serve as an essential line of defense by continuously assessing the concentration of oil mist—tiny droplets suspended in the air within the engine’s crankcase. When the oil mist levels become excessive, conditions are ripe for ignition, which could lead to a dangerous crankcase explosion.

Role in Preventing Crankcase Explosions

Oil mist detectors play a vital role in preventing such explosions. By providing real-time alerts to operators when oil mist levels approach dangerous thresholds, these detectors allow for immediate corrective action to be taken, reducing the risk of ignition. This early-warning system is fundamental to maintaining safe operating conditions, helping to protect both equipment and personnel from potentially catastrophic engine failures.

The Purpose of an Oil Mist Detector

An oil mist detector is an essential safety device that plays a critical role in real-time monitoring of engine conditions, particularly in large industrial and marine engines. By continuously assessing oil mist levels within the crankcase, this device ensures the safe operation of engines and helps prevent dangerous incidents.

Primary Function Explained

The primary function of an oil mist detector is to monitor and detect rising levels of oil mist in the crankcase. Excessive oil mist indicates a potential risk for crankcase explosions, as mist particles can ignite under high-pressure and high-temperature conditions. Through real-time monitoring, the detector alerts operators to unsafe levels, allowing for quick corrective actions to maintain engine safety.

Importance of Detecting Excessive Oil Mist

Excessive oil mist poses significant risks, including engine overheating, mechanical failure, and even explosions. When left unchecked, high oil mist concentrations can lead to critical malfunctions, endangering both equipment and personnel. The early warning provided by oil mist detectors is crucial for identifying these hazards before they escalate.

Causes of Oil Mist Formation

Oil mist buildup can occur due to a variety of factors, such as:

- Worn or Damaged Components: Parts with excessive wear can cause increased friction and oil vaporization.

- High Engine Temperatures: Elevated temperatures increase oil vapor formation, leading to higher mist concentrations.

- Oil Vaporization: Rapid oil vaporization can occur under intense engine conditions, especially if oil levels or quality are not properly maintained.

How Oil Mist Detectors Work

Oil mist detectors are designed with advanced technology to continuously sense and measure oil mist density within engine crankcases, ensuring early detection of potentially dangerous conditions.

Detection Mechanism

These detectors typically rely on sophisticated sensors that monitor the concentration of oil mist particles in the air. By analyzing the density of oil mist, they can determine if it’s reaching levels that might pose a risk, allowing operators to take preventative action before issues escalate.

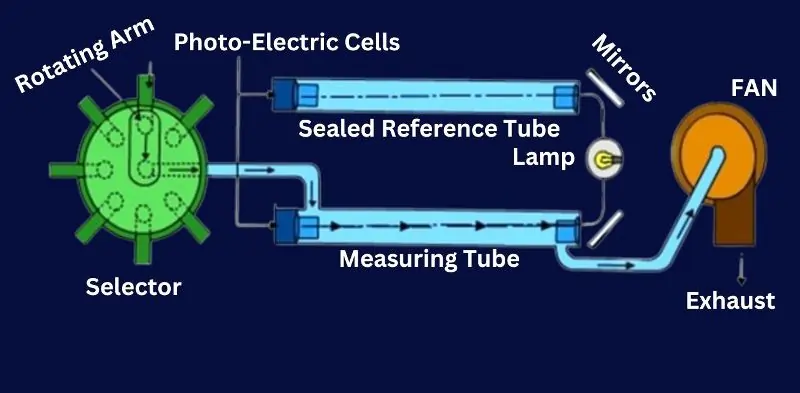

Types of Sensors Used

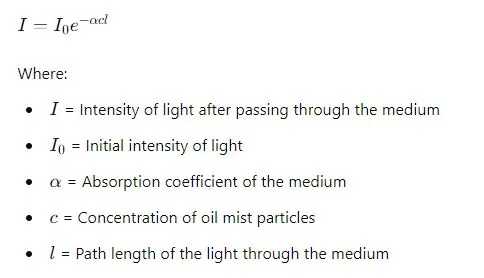

Common sensors used in oil mist detectors include optical sensors and photometers. Optical sensors measure the amount of light scattered by oil mist particles, which correlates with their concentration in the air. Photometers, on the other hand, measure light absorption by the oil mist, providing accurate data on mist density.

Measurement of Oil Mist Density

The sensors convert detected light scattering or absorption levels into quantitative data, which is then processed to display real-time oil mist density. When density readings exceed safe thresholds, the detector triggers alarms, alerting operators to take immediate corrective actions to avoid potential crankcase explosions. This transformation of sensor data into actionable alerts is a core component of effective engine safety systems.

Alert System of an Oil Mist Detector

The alert system of an oil mist detector is designed to provide immediate warnings to operators when oil mist levels approach or exceed safe limits, preventing potentially dangerous situations within engine crankcases.

Triggering Alarms

Oil mist detectors are equipped with threshold settings calibrated to detect hazardous oil mist concentrations. When these thresholds are reached, the detector’s alert system is activated, triggering alarms that notify operators of the elevated oil mist levels. In critical situations, the system may initiate automatic engine shutdowns to prevent further risk, depending on the configuration and safety protocols in place.

Safety Protocols When Thresholds Are Exceeded

When oil mist levels surpass safe limits, specific safety procedures should be followed to mitigate risks. These protocols typically include shutting down the engine to prevent ignition within the crankcase, ventilating the affected area to reduce mist levels, and conducting a thorough inspection to identify the cause of excessive mist generation. By following these safety steps, operators can minimize the risk of crankcase explosions and maintain a secure engine environment.

Explanation of an Oil Mist Detector

Oil mist detectors are intricate devices that combine various components to monitor and measure oil mist levels, alerting operators to potential hazards within engine crankcases. Here’s a detailed look at their components, working mechanism, and the key principles involved in their operation.

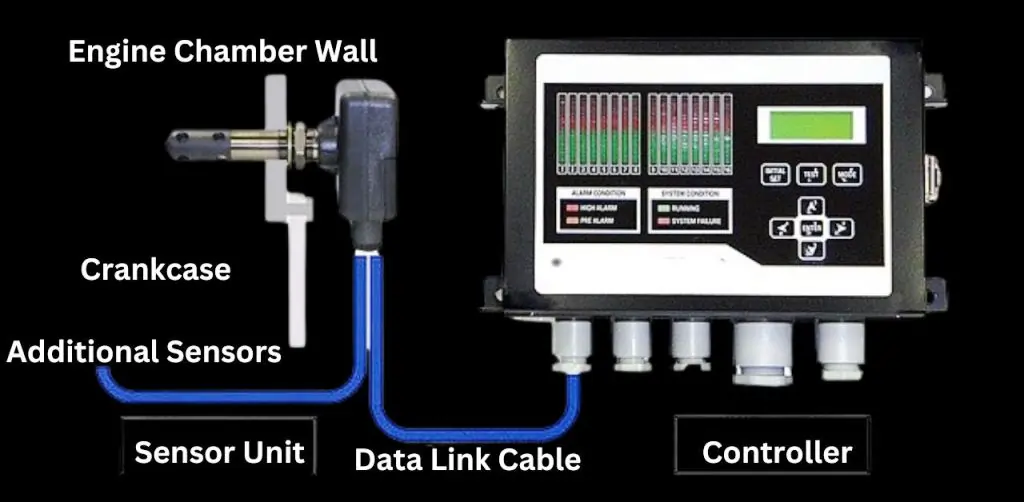

Components and Their Functions

- Sensors: The core of an oil mist detector, sensors detect the presence and concentration of oil mist particles. Optical sensors and photometers are commonly used to measure mist density by analyzing light interactions with mist particles.

- Data Processor: This component analyzes sensor data, processing information on mist concentration levels and comparing it to preset safety thresholds.

- Alarms: The alert system activates when oil mist levels reach or exceed set thresholds, issuing warnings or initiating automatic shutdowns depending on the severity of the reading.

- Display Interface: Operators receive real-time data and alerts through a user-friendly interface, enabling them to monitor mist levels and react promptly to hazards.

Working Mechanism

The detection process starts with sensors measuring oil mist density through light interactions. Data from the sensors is processed to calculate the concentration of mist particles. If levels approach unsafe thresholds, alarms are triggered, alerting operators to take immediate action or, in severe cases, shutting down the engine automatically.

Key Formulas for Understanding Oil Mist Detectors

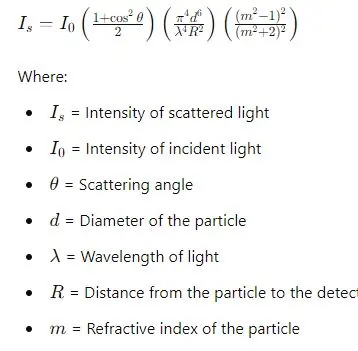

1. Light Scattering and Oil Mist Concentration

Depending on the size of the oil mist particles in relation to the light’s wavelength, the Rayleigh or Mie scattering theories can be used to illustrate the idea of light scattering. For small particles (Rayleigh scattering):

2. Beer-Lambert Law

For understanding the attenuation of light as it passes through a medium containing oil mist:

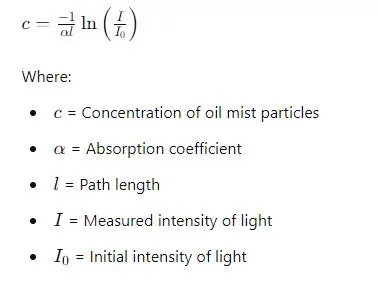

3. Concentration Calculation

To calculate the concentration of oil mist particles from the measured light intensity:

Essential Tips for Using Oil Mist Detectors

To ensure optimal performance and safety, following best practices when using oil mist detectors is essential. Here are six key tips to help maximize the reliability and effectiveness of these devices:

Tip 1: Regular Maintenance

Scheduled maintenance is crucial for keeping oil mist detectors accurate and fully operational. Routine checks help identify any wear, dust accumulation, or sensor drift that could affect performance, ensuring the detector is ready to respond to hazardous conditions.

Tip 2: Proper Installation

Correct installation is vital to the accurate functioning of an oil mist detector. Install the detector in a location where it can effectively monitor oil mist levels in the crankcase, as per the manufacturer’s specifications. Proper positioning ensures the detector accurately measures oil mist concentrations and minimizes false readings.

Tip 3: Calibration

Regular calibration is necessary to maintain the detector’s accuracy. Calibration aligns the detector with baseline measurements, ensuring that readings remain reliable over time. Adhere to recommended calibration intervals, which vary depending on the model and operating conditions, for the best results.

Tip 4: Training Staff

Proper staff training is essential for effective monitoring and response. Training should cover how to operate the detector, interpret readings, and follow safety protocols in case of an alarm. Knowledgeable operators can better recognize and respond to alerts, maintaining engine safety.

Tip 5: Monitoring Performance

Ongoing performance monitoring allows operators to detect potential issues with the detector itself, such as sensor degradation or inaccurate readings. Regular performance checks help maintain the detector’s reliability, preventing dangerous accumulations of oil mist from going undetected.

Tip 6: Integration with Other Safety Systems

Integrating the oil mist detector with other safety systems, such as automatic shutdowns or alarms, enhances overall engine safety. When connected to a shutdown mechanism, the detector can automatically halt engine operation if mist levels exceed safe limits, preventing escalation and potential damage.

By following these essential tips, operators can ensure their oil mist detectors perform effectively, maintaining a safer engine environment and reducing the risk of hazardous incidents.

FAQ on Oil Mist Detector

Q: What is the primary function of an oil mist detector?

A: To prevent explosions by detecting and measuring oil mist in the crankcase.

Q: How does an oil mist detector alert operators to high oil mist levels?

A: By setting off safety precautions and setting off visual and auditory alerts.

Q: Why is regular calibration of an oil mist detector important?

A: To ensure accurate and reliable detection of oil mist.

Q: What are the typical reasons why engines produce oil mist?

A: Overheating, friction, mechanical failures, hot spots, and exhaust blow-by.

Conclusion

Oil mist detectors are essential for maintaining the safety and efficiency of large marine diesel engines and industrial machinery. By continuously monitoring oil mist levels, these devices prevent dangerous crankcase explosions, ensure operational integrity, and protect both equipment and personnel. Regular maintenance, proper installation, calibration, and staff training are critical to their effective use. Implementing oil mist detectors as part of a comprehensive safety system is a proactive step towards safeguarding your operations and ensuring long-term reliability.